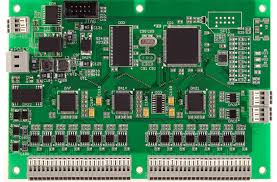

Lead-time of PCB fabrication is arguably the most important factor in electronics manufacturing that can significantly impact how quickly a product goes through ideation to physical delivery. This article looks at how speeding up the delivery of PCBs enables innovation, shortens time to market and leads to redefining competition.

Impact on Time to Market

Quickturn PCB fabrication saves time and help to get to the market quicker. PCB production traditionally had a turnaround time of 12hrs to several days, or even weeks based on design complexity and the number of layers required. Today, by using these modern tools and processes some companies are able to deliver a PCB in just 24 hours.

A latest survey in the industry suggests that simply reducing the PCB production time by 20% can reduce up to 15% of overall product development time. This is because quick PCB turnaround results in rapid prototyping leading to more iterations and hence, deliverable improvement within the limited time.

Affordability and ROI, respectively.

Higher-speed PCB manufacturing not only saves a lot of time but also influences on the economics of project development. Development phases that take less time often mean more labor hours and fewer overhead costs. For example, the overheads per week/terms for a standard PCB order would cost around $10k. Suprath, the shorter fabrication time can save millions on a large scale construction project improving return on investment.

In addition, faster production means the ability for businesses to get products into the market more quickly may enable an early move where they are first to release new or improved products and therefore take a lead on market share. In Africa, the classic competitive responses toward a new product are unlikely to occur in such great frequencies due to most products being unknown or even unavailable in many places and therefore few local companies had strategies fully developed for these purposes. That early mover advantage results in better profit margins and stronger brandingacey

Rapid Prototyping to Drive Innovation

Speed is just as important⊕A faster CEM boards in given moment often offer a rapid PCB fabrication whereas others take ages for the purpose of making protypes. Designers can then use the resulting functional PCB to experiment with and refine their design faster than ever before. This iterative loop encourages creativity, incorporating feedback loops into design on the fly to explore what might be possible from a technical perspective.

Companies using Quick turn PCBs are able to develop a new product design and replace existing designs more frequently thus resulting higher innovation and broader product portfolio. One big tech company shared that just moving to faster PCB production drove a 30% patent filing increase over two years, showing how innovation can be stymied.

Conclusion

PCB fabrication speed is much more than just a metric of manufacturing efficiency, as it can be the most consequential factor affecting product development in the electronics space. The strategic advantage obtained by quick-turn PCBs, provides companies with a stepping-stone to quicken iterations, lower costs and cut time-to-market; leading to more innovation, profitability and market success.